WPL612 WPL610 WPL608

| WPL Driver: | Printer driver for most Wasp WPL printers |

| DiagTool: | WPL Printer Diagnostic Tool (DiagTool) |

| Manuals: |

Images:

|

|

Poor Print Quality

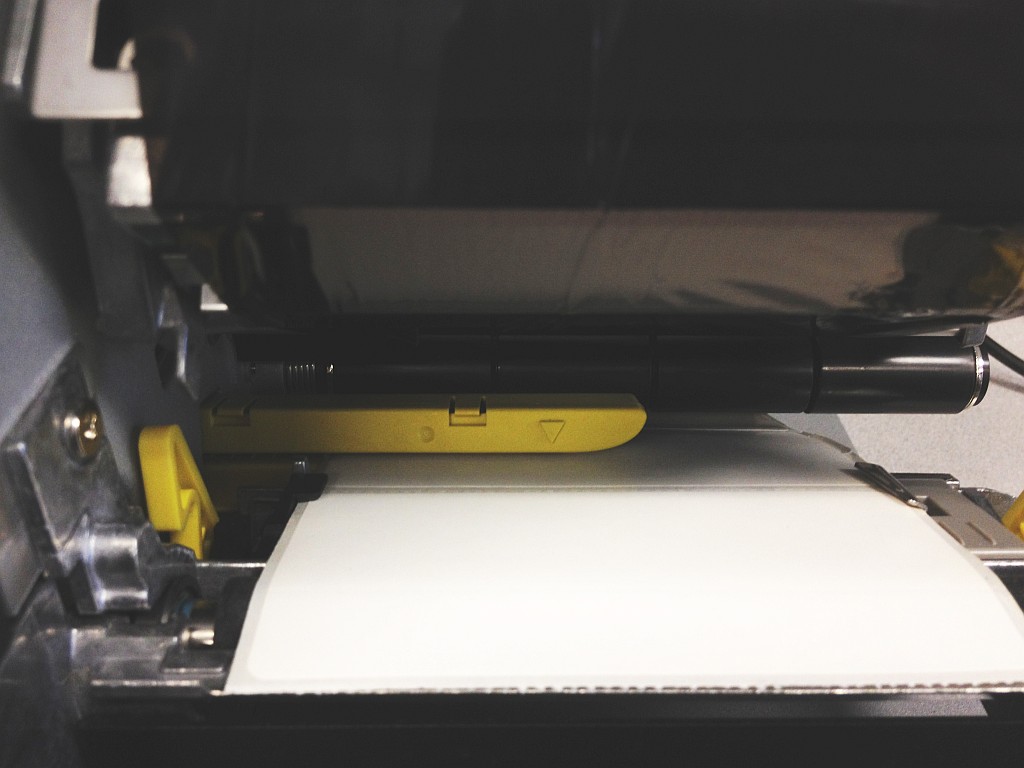

| Poor Quality > Ribbon & media is loaded incorrectly | * Reload the supply. |

| Gray Line on blank label > Dust or adhesive accumulation on the print head. |

* Clean the printhead.

|

| Poor Quality > Print density is not set properly. | Run printer self-test and check the print head test pattern if there is dot missing in the pattern. |

| Poor Quality > Printhead element is damaged. | Repair |

| Poor Quality > Ribbon and media are incompatible. | Change proper ribbon or proper label media. |

| Wrinkle problems > The printhead pressure is not set properly | Adjust the printhead pressure adjustment knob. Use the Z-axis adjustment knob to fine tune the pressure. |

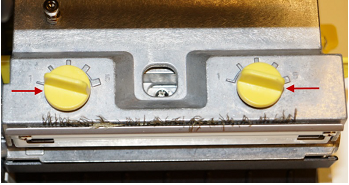

Print Head Pressure Adjustment Knob

Because the printer’s paper alignment is to the left side of mechanism, different media widths require different pressure to print correctly.

If width is 4” adjust both knobs. If width is < 2", increase the left side clockwise and decrease the right side counter-clockwise to 1.

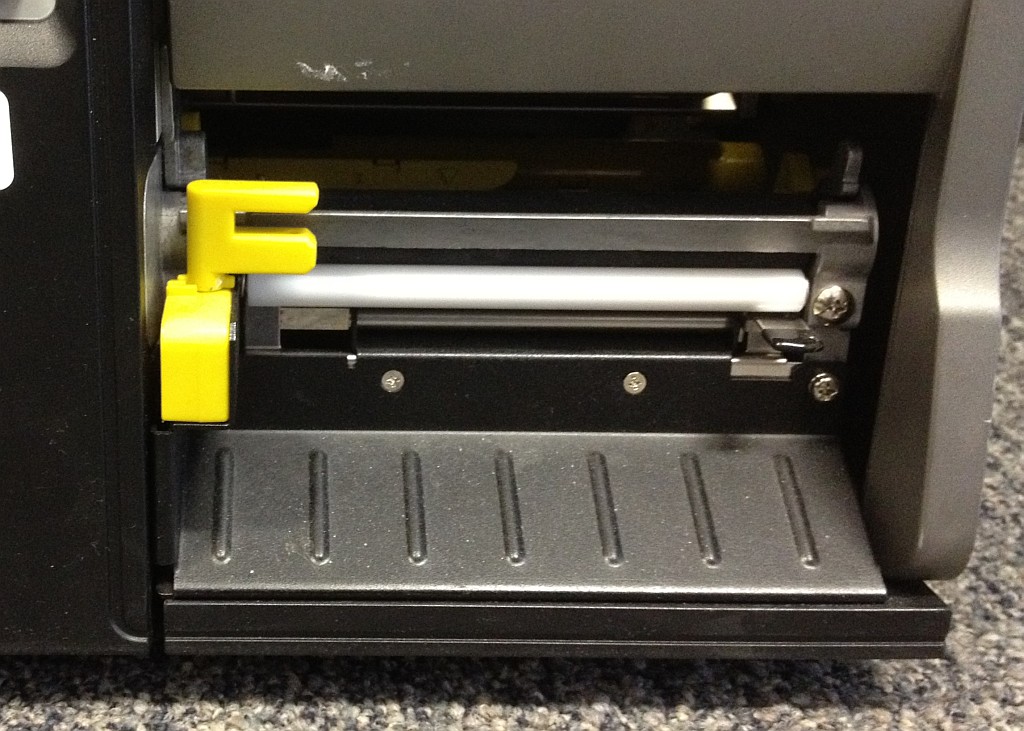

Print Head Burn Line Adjustment Knob

The print head burn line adjustment knobs are used to fine tune the print quality for different thickness of media. Turning the knobs adjusts the print head’s burn line forward or backward as it relates to the platen roller.

Caution: Incorrectly adjusting these knobs can lead to poor print quality and may cause damage to the printer.

On the WPL612 the screws have recessed hex heads for an Allen wrench or hex driver. On the WPL610 and WPL608, the screws are slotted for a flathead screwdriver.