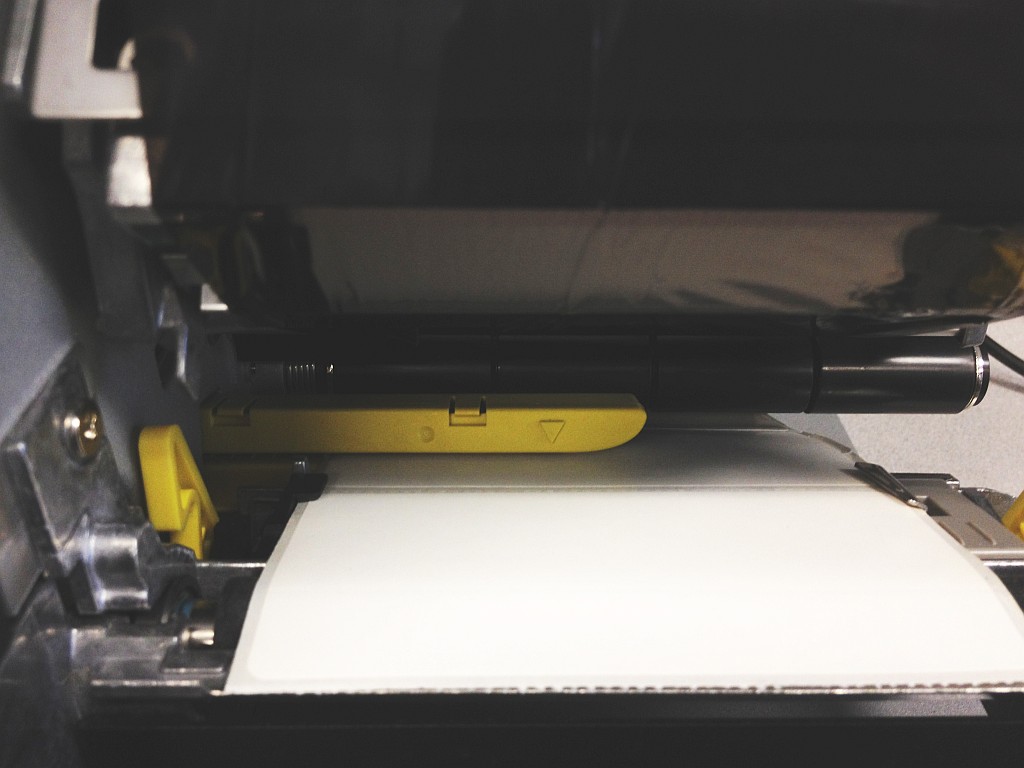

The gap sensor is located in the housing between the triangles/arrows. The gap sensor housing moves from side to side (reach in from the right, below the labels), and use two fingers to grasp the tab), and must be positioned so that the sensor can "see" the gap between the labels, as the stock is pulled past the sensor. If the sensor is all the way to the left or right, it probably can't see the gap, and you'll receive paper jam or other errors at every print.

If the printer will not successfully auto-calibrate, it's possible there is paper debris or a stuck label blocking the sensor. You may be able to clear paper debris with blast(s) of compressed air. It may also be necessary to closely examine the sensor and manually remove obstructions.